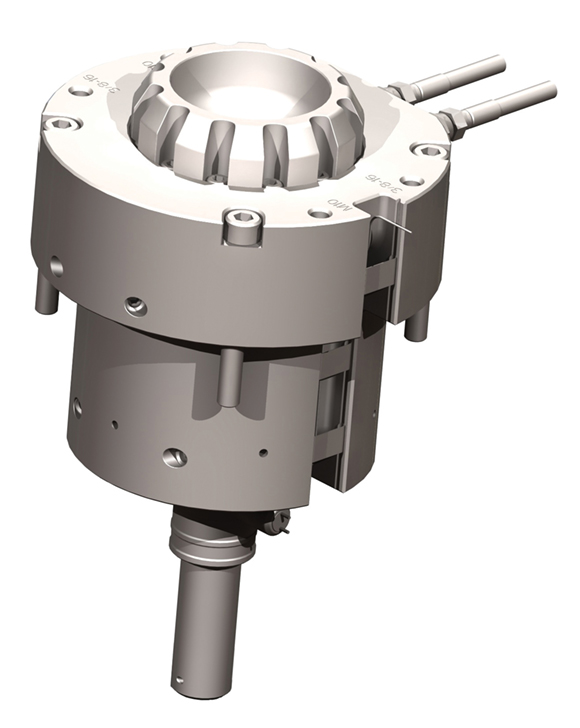

EASY, ECONOMICAL SINGLE CAVITY VALVE GATING

Engineered to deliver exceptional part quality with today’s challenging abrasive, corrosive, shear and temperature sensitive resins such as PC, PC-ABS and PMMA. Critical for demanding Automotive Lenses, Medical, Personal Care and Technical molding applications.

Features

In-Line Flush Mount Design

- Buried in plates for added protection.

- Even force distribution.

- Valve gated for larger process window.

Full Stainless Steel Construction

- Greatest resistance to corrosive and abrasive resins.

- Helps prevent contamination defects from premature wear.

- Extends service life.

Brazed Heater Technology

- Excellent thermal profile (10% max variance*) for tight process control.

- Compatible with shear and temperature sensitive resins.

- Superior reliability minimizes downtime.

- Eliminates spare heater costs.

In-Press Service Capabilities

- Quickly and easily maintained.

*Based on internal test results.

Specifications

- Compatible Nozzles: Dura+, Master-Series

- Shot Range: 50g – 5,000g

- Runner Ø Range: 11 - 22mm (0.43" - 0.87")

- Nozzle Length Range: 28 - 488mm (1.10" – 19.21")

- Bore Cut-Out Ø (Min): 32mm (1.26")

- Actuation Options: Pneumatic or Hydraulic

- Available as an assembly only

Available Gating Styles

Valved (Dura+ Nozzles)

- Bi-Metallic Ball Nose

- Hot Valve (+Extended)

- Bi-Metallic C-Valve (+Extended)

Valved (Master-Series Nozzles)

- Accu-Valve MX

- Accu-Valve CX

- Cylindrical Hot Valve

- C-Valve

- Hot Valve